A CHALLENGING BUT FUN JOB

OFFSHORE OIL RIG RECYCLING

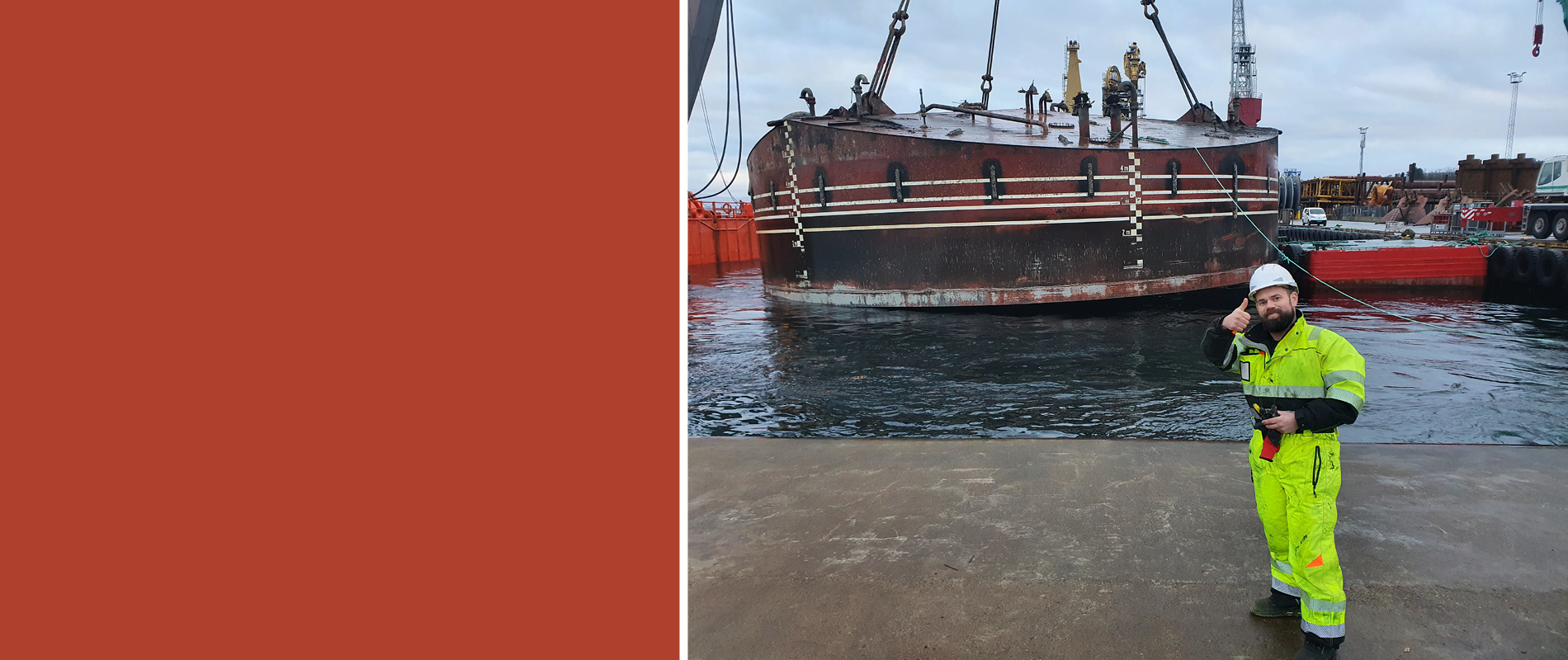

Stena Recycling Norway’s solution-oriented way of tackling challenges is one of the reasons customers think they are a reliable partner when it comes to carrying out heavy-duty recycling commissions. One of their largest projects has been to handle spudcans, which are large and heavy inverted cones that are part of the legs of a liftable offshore oil rig.

The spudcan project was a very challenging and time-consuming project with several tough conditions to manage, including a tight timeframe and extreme heavy-duty lifting.

“We have the best solution,” says Øyvind Sandve, Sales and Marketing Manager Rogaland at Stena Recycling Norway. “Apart from the risky business of lifting those extremely heavy constructions from the water onto a pier, our customer Westcon also knew that we could handle all the material in the best way for recycling purposes, and that we could get it all done within their tough timeframe.”

A RISKY OPERATION INCLUDING MANY CHALLENGES

The biggest challenge was to lift the three spudcans out of the water as all parts of the lifting process are dangerous. Calculating the weight without blueprints was hard, knowing that the commissioned heavy-duty lifting vessel HLV Uglen’s max lift capacity was very near the estimated weight of each spudcan. The design of the spudcans makes them hold tons of water. Their shape creates a vacuum that holds the water as they are lifted. During the lift, there is a point where a lot of water suddenly rushes out of them. Movement, weight, and surroundings all influence how well the lifting process works at this point. To solve this, holes had to be made to let the water flow out more slowly and in a more controlled way. It was estimated that each spudcan held at least 30 tons of water. However, the crew soon realized that each spudcan was heavier than first anticipated. The captain of HLV Uglen decided that a reduction of metal weight had to be done. Stena Recycling then had to separate the fasteners from the spudcans, which reduced the weight enough for

HLV Uglen to be able to lift them.

It took Stena Recycling Norway more than seven days to get it all done. The preparations for the lift were most time-consuming as the lift itself only took a total of ten hours. Luckily, the weather stayed calm and steady, as required, for the duration of the process.

Øyvind Sandve, Sales and Marketing Manager Rogaland at Stena Recycling Norway.

“Altogether, I worked some 85 hours those days. I’m proud that we could meet the challenges along the way, even if there were some iffy moments. It’s for sure a heavy, cold, sea-based, and overall tough job, but always fun,” says Øyvind.

The project included a lot more than the process of conducting the lift. Calculating costs, preparing the pier, logistics, manning, and planning for a safe and secure lift all took a lot of time. In the end, the total amount of steel lifted was 2,200 tons, which was later freighted to Mo i Rana in Norway for recycling.

“This is what we do. We solve problems, using our excellent network of knowledge. We support our customers all the way. With the spudcans it involved moving them on the sea, lifting them, recycling them. All whilst we kept the costs down, solved problems as they occurred, and made sure all the material went back into the loop. Proud work, every day of the week!” Øyvind concludes.