STENA RECYCLING INVESTS IN

NEW BATTERY RECYCLING PLANT

Stena Recycling is investing in a new battery recycling process. The investment involves a brand new facility in Halmstad and will make it possible to recycle 95 per cent of a lithium-ion battery, which is the most common battery used in electric vehicles.

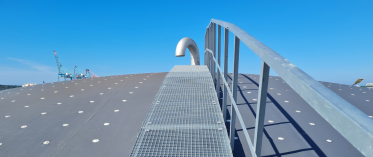

This autumn, the first ground will be broken on what will become Sweden’s, and one of Europe’s, most advanced battery recycling facilities. The new plant represents an investment of around 250 million SEK and will be located adjacent to the Stena Nordic Recycling Center in Halmstad.

“We see a strong growth in the sale of electric vehicles where we need to meet our customers’ needs to dispose of spent batteries in a safe and environmentally sound way. This major investment is part of our strategy to be a leader in the collection and mechanical processing of lithium-ion batteries to establish a circular cycle for batteries,” says Fredrik Pettersson, Managing Director of Stena Recycling Sweden.

According to EV-volumes.com, sales of electric vehicles increased by 43 per cent globally in 2020. Furthermore, the number of lithium-ion batteries used in vehicles is expected to increase almost tenfold over the next decade, according to a report by Circular Energy Storage Research & Consulting.

“We are now responding to market demand. We are proud to offer a circular solution for lithium-ion batteries. It will be a big win for the environment and for the life cycle of the batteries when we recover critical metals such as lithium, nickel and cobalt, which are in short supply, worldwide,” says Fredrik Pettersson.

KEY TO ACHIEVING A CIRCULAR RAW MATERIALS CHAIN

The batteries will initially be collected via Stena Recycling’s 90 facilities in Sweden, and eventually via other countries where Stena Recycling operates. Initial sorting takes place at these facilities, but most of the recycling is then done at the new facility in Halmstad. A collaboration with the multinational company Johnson Matthey also adds another process step to produce fully refined materials that can be used in the production of new lithium-ion batteries. Closing the loop and creating new raw materials for batteries from recycling is key to achieving a circular raw materials chain.

“There are plenty of major players looking to enter this market, but few have Stena Recycling’s capabilities based on our existing infrastructure, customer base, expertise and experience. Thanks to this investment, we are taking an important step towards becoming one of Europe’s leading players in battery recycling,” Fredrik Pettersson ends.